News

When printers ask me to recommend a thermal CTP plate for offset printing, they rarely start with "What is the coating chemistry?" They start with the problems they want to eliminate: inconsistent dots across a long run, scumming when the dampening swings, press stops from plate wear, or wasted hours because imaging and processing do not match the shop's reality.

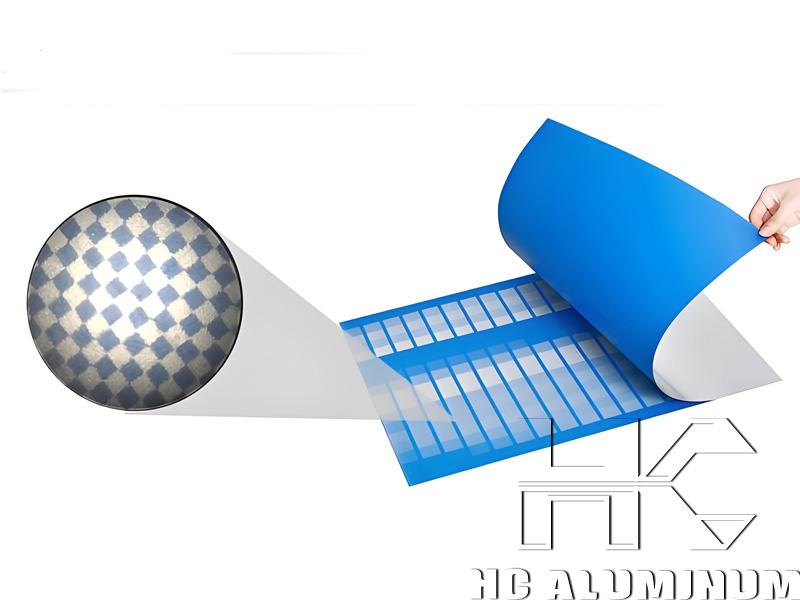

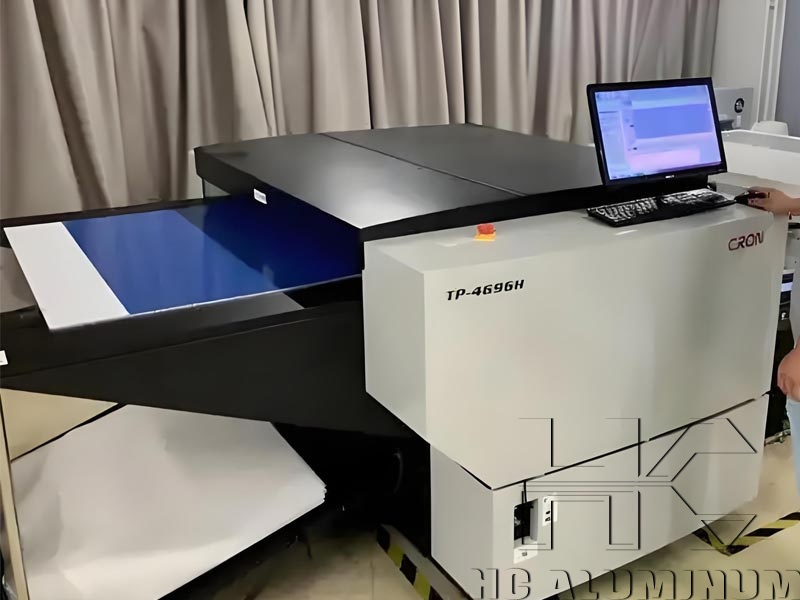

A thermal CTP plate sits at the center of that reality. It converts digital data into a press-ready image with excellent repeatability, high resolution, and strong tolerance to day-to-day variation. Thermal imaging is also forgiving in mixed shop environments because it is far less sensitive to incidental light than violet systems, and it tends to deliver stable exposure latitude when the platesetter is well maintained.

What a thermal CTP plate actually does (and why it is trusted)

Thermal plates are imaged by an infrared laser, typically around 830 nm. The laser energy triggers a change in the imaging layer, creating image and non-image areas that will later accept ink or water appropriately. In practice, thermal plates are valued for three performance traits that affect profit on press:

Dot stability at high line screens: smoother highlights, cleaner vignettes, and reduced dot loss during longer runs.

Broad exposure latitude: less sensitivity to minor drift in laser power or focus compared with some alternative technologies.

Press robustness: better resistance to abrasion and chemicals, which matters when you run aggressive inks, higher alcohol substitutes, or need long run lengths.

Thermal CTP is not just "a plate type." It is an imaging-and-press system. When the plate, platesetter, processor (if applicable), and fountain solution are aligned, the result is predictable color and less make-ready waste.

Key performance specifications that clients should evaluate

Every supplier can quote thickness and size. The questions that separate a good plate purchase from a painful one are about performance windows.

1) Imaging resolution and dot reproduction

Thermal plates commonly support high resolution output suitable for commercial sheetfed and web offset, including fine text and demanding screens. If your work includes 175–200 lpi (or stochastic screening), ask for:

Verified dot reproduction in the 1–99% tonal range

Stable microtext and thin rules

Consistent results across plate batches

A practical check I like is a control wedge plus a vignettes test: the "tail" of a vignette reveals whether the plate can hold small dots without breaking up or filling in.

2) Run length (realistic, not theoretical)

Run length depends on press conditions: ink type, paper abrasiveness, blanket condition, and whether baking is used. Rather than chasing an inflated number, align the plate to your actual needs:

Commercial work (brochures, books, catalogs): prioritize clean highlight holding and easy roll-up.

Packaging (coated boards, heavier coverage): prioritize wear resistance and chemical durability.

If you routinely print abrasive stocks or high solid coverage, it is worth selecting a higher durability thermal plate even if the imaging latitude is similar.

3) Developer compatibility and processing stability

For processed thermal plates, stable development is the difference between consistent dot gain and a daily firefight.

Look for:

A plate that tolerates reasonable developer conductivity drift

Clear guidance on developer temperature and replenishment

Low sludge tendency and good bath life

For plants aiming to reduce chemistry, modern plate options can also support cleaner processing or reduced replenishment, helping lower operating cost and environmental load.

4) Ink-water balance on press

A thermal CTP plate for offset printing should start fast and stay clean. The coating design influences how quickly the plate desensitizes in non-image areas and how robust the image area is under strong emulsification.

On press, this shows up as:

Faster make-ready and fewer sheets to color

Lower risk of background toning when dampening fluctuates

More stable color across the run

Choosing the right thermal plate configuration for your workflow

Thermal plates come in different structures (such as single layer or multi-layer coatings) optimized for different goals: speed, latitude, durability, or processing tolerance.

If your priority is straightforward commercial production with consistent imaging and press performance, a well-matched thermal CTP plate is typically the most economical way to stabilize output.

If you are printing high-resolution work and want the familiar performance characteristics of a positive-working system, a positive thermal CTP plate can be a strong choice where workflow preference or process control favors that behavior.

Illustrative examples from typical print jobs

Example 1: Catalog printing with demanding skin tones

A sheetfed commercial printer running 175 lpi experiences visible "grain" in highlights and unstable flesh tones between press starts. They switch to a thermal plate with stronger dot anchoring and tighten the platesetter calibration (laser power and focus check). Result:

Highlights hold cleaner at 2–4% without speckling

Color stabilizes sooner after restart

Less time spent chasing dot gain in midtones

The biggest gain is not only the plate itself; it is the repeatability that lets prepress profiles remain valid for longer.

Example 2: Long-run textbook work with frequent wash-ups

A book printer runs long forms and performs more wash-ups due to schedule interruptions. Plate wear and chemical attack cause gradual loss of density in solids and edge roughness in fine rules.

A more durable thermal plate reduces wear sensitivity and maintains solid density through repeated wash cycles, lowering plate remakes and preserving registration and sharpness.

Example 3: Mixed paper sources and variable dampening

A plant with mixed paper lots sees background scumming on some days, especially when water quality shifts. A thermal plate with strong non-image desensitization behavior and better tolerance to dampening variation helps keep backgrounds clean, reducing stop-and-clean events.

What to ask your supplier (to avoid hidden downtime)

Thermal plates are a repeat purchase, so small deviations become expensive. I recommend asking for these practical details:

Batch consistency controls: How is coating weight and sensitivity controlled across batches?

Platesetter compatibility: Confirm wavelength and recommended exposure energy window.

Processing parameters: Developer type, temperature range, dwell time, and replenishment guidance.

Storage and handling: Shelf life, humidity range, and how packaging protects against edge damage.

Handling and storage tips that protect plate performance

Even a premium thermal plate can underperform if it is stored poorly. Simple discipline pays back:

Store plates sealed in original packaging, away from heat sources.

Avoid high humidity that can affect coating response and oxidation.

Let plates acclimate to pressroom temperature before imaging to prevent condensation.

Handle edges carefully; micro-damage at the edge can become visible as streaks in solids.

Why thermal CTP remains a smart investment for offset printing

Offset printing rewards consistency: the same file should output the same plate, and the same plate should behave predictably on press. A thermal CTP plate delivers that consistency when the system is tuned, making it easier to standardize color, reduce make-ready time, and protect margins on both short and long runs.

If you want help selecting a thermal plate based on your press type, target run length, screening method, and processing constraints, share your current plate specs and typical jobs. The fastest way to improve results is to match the plate's real operating window to how your pressroom actually runs.

PRODUCTS

ONLINE CONSULTATION

If you have any questions, please contact us and we will contact you as soon as possible.

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.