News

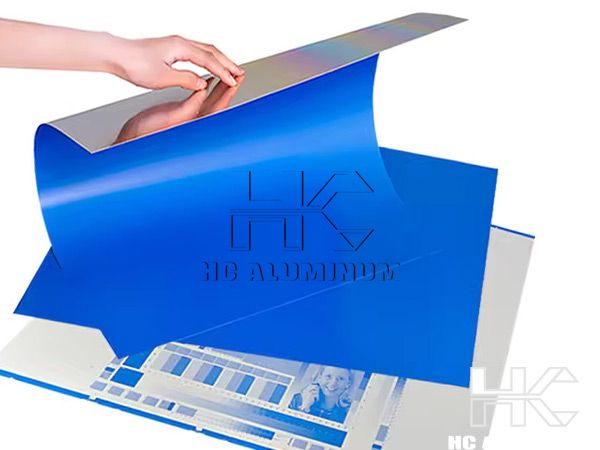

Positive printing plates are a common type of printing plates in lithography (offset printing). The imaging principle is based on the exposure of positive negative film (the image part is transparent and the non-image part is opaque). Compared with negative printing plates, the image part of the positive plate is cured by exposure during the platemaking process, and the non-image part is removed, eventually forming an oleophilic printing surface, which is suitable for batch printing needs.

1. Printing principle of positive printing plates

(1). Core principle:

The photosensitive layer of the positive plate (usually diazo resin or photosensitive resin material) will undergo a photochemical reaction when exposed to ultraviolet light. When the positive negative film is covered on the printing plate and exposed, the transparent image part of the film allows light to penetrate, causing the photosensitive layer to cross-link and cure; the non-image part is not exposed because of the negative film, and the photosensitive layer remains soluble.

(2). Platemaking process:

- Exposure: The positive negative film is tightly attached to the printing plate, and the image part is irradiated with ultraviolet light, and the photosensitive layer of the image part is cured.

- Development: Wash the printing plate with developer, the unexposed non-image part of the photosensitive layer is dissolved, exposing the base (usually aluminum), forming a hydrophilic surface; the solidified image part is retained to form an oleophilic surface.

- Post-processing: baking the plate (improving printing resistance), gluing (protecting the plate surface), and completing the plate making.

(3). Difference from negative plate:

Negative plate requires negative film (the image part is opaque), and the non-image part is solidified after exposure, which is opposite to the imaging logic of positive plate.

2. Main types of positive printing plates

(1). By plate making technology

- Traditional positive PS plate (pre-coated photosensitive plate)

Based on diazo photosensitive resin, it needs to be matched with negative film for plate making, with mature technology and low cost.

- Positive CTP plate (computer to plate)

No negative film is required, it is directly exposed by laser through CTP equipment, with high resolution, suitable for digital plate making.

(2). By base material

- Aluminum-based positive plate

High printability (up to 100,000 prints or more), it is the mainstream base material.

- Paper-based or plastic-based positive plate (flexible base)

Lightweight, suitable for small-format or special substrate printing, low printability.

(3). By photosensitive layer material

- Diazo-type positive plate

High sensitivity, suitable for rapid plate making, widely used in commercial printing.

- Photopolymerization positive plate

Stronger printability, suitable for long-run printing (such as newspapers, packaging).

(4). By environmental characteristics

- Process-free positive plate (chemical development-free)

No developer is required, reducing waste liquid pollution, in line with environmental protection trends, and gradually replacing traditional plates.

3. Market share of positive printing plate:

Positive printing plates account for more than 60% of lithographic printing plates, among which traditional positive PS plates still occupy a certain share due to their cost advantages, but with the popularization of digital platemaking, the market share of positive CTP plates has increased year by year (it is expected to account for more than 70% of lithographic CTP plates in 2025).

Segment share:

- Commercial printing (magazines, advertising): Positive CTP plates account for more than 80% due to their high resolution and fast platemaking characteristics.

- Packaging printing: Positive plates (especially photopolymer plates with high printability) account for about 70%, which are used for mass production of cartons, labels, etc.

- Publishing and printing (books, newspapers): Traditional positive PS plates and positive CTP plates coexist, and the former accounts for about 50% of medium and short-run printing due to its low cost.

4. Core advantages of positive printing plates:

- Mature platemaking process:

Traditional positive PS plate technology has been developed for decades, with simple operation and low requirements for operators, suitable for small and medium-sized printing plants.

- High resolution and clarity:

Positive CTP plates can achieve a screen line number of more than 200LPI, meeting the printing needs of fine graphics (such as albums, trademarks).

- Strong printability:

The aluminum-based positive plate can reach a printability of 1 million times after baking, which is suitable for long-run printing (such as newspapers, bulk commodity packaging).

- Cost advantage:

The unit price of traditional positive PS plates is low, and the investment cost of supporting equipment (such as platemaking machines) is lower than that of CTP equipment, which is suitable for medium and short run printing.

- Environmental upgrade potential:

The non-processed positive CTP plate does not require chemical development, reduces waste liquid discharge, and complies with environmental protection policies (such as EU REACH regulations).

5. Application scenarios of positive printing plates:

- Commercial printing:

High-end magazines, advertising brochures, posters: Use the high resolution of positive CTP plates to present delicate colors.

Commercial leaflets, DM sheets: Traditional positive PS plates meet medium and short run needs at low cost.

- Packaging and printing:

Pharmaceutical packaging, food gift boxes: The dot reproduction ability of the positive plate ensures clear patterns and meets hygiene standards.

Beverage labels, cosmetic packaging: The positive plate with high printability supports high-speed printing production lines.

- Publishing and printing:

Textbooks, hardcover books: The stability of the positive plate ensures color consistency during batch printing.

Newspapers, periodicals: Traditional positive PS plates are combined with rapid plate making to meet the timeliness requirements of daily newspapers.

- Special fields:

Anti-counterfeiting printing: Positive plates can realize anti-counterfeiting processes such as microtext and FM network.

Digital proofing: Positive CTP plates are combined with digital printing for rapid proofing and small batch production.

Positive printing plates occupy an important position in the printing industry due to their high quality, high efficiency and wide applicability.

PRODUCTS

ONLINE CONSULTATION

If you have any questions, please contact us and we will contact you as soon as possible.

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.