News

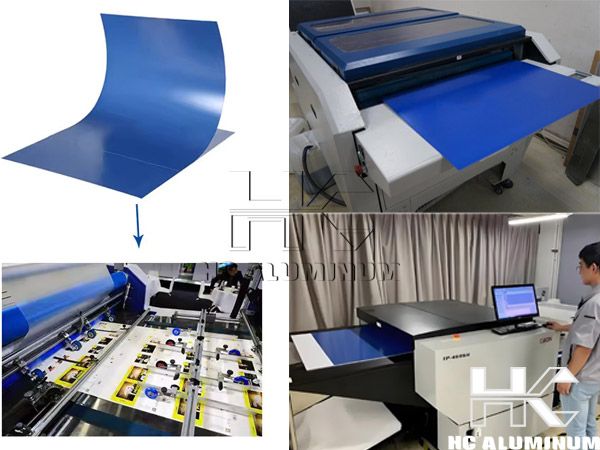

The positive plate for offset printing is a lithographic printing plate based on the principle of photochemical reaction. Its core feature is that after being exposed through the positive film (positive negative), the image part retains the photosensitive layer, and the blank part is dissolved by the developer, forming an oleophilic and hydrophobic image area and a hydrophilic and oleophobic blank area. Positive plates is one of the most mainstream and widely used printing plate types in offset printing.

For a positive plate, positive refers to the film (or digital file) used for plate making is a positive image. That is, the image area on the film is black and opaque, and the non-image area is transparent. Positive printing plates are mainly divided into two types: PS (Photographic Plate) positive plate and CTP (Computer to Plate) positive plate.

Performance advantages of positive plates for offset printing:

- Accurate dot reproduction:

The dot enlargement value of the positive type plate is small when the plate is exposed (usually ≤15%), which can faithfully reproduce the gradation of the original manuscript, especially suitable for 4-color dot printing.

- Easy operation:

Directly use positive film to make plates, no need to perform masking like negative plates, intuitive and efficient platemaking.

- Reliable printability:

The anodized aluminum base and the baking process allow the printing plate to withstand hundreds of thousands of prints and can be stored for 6 months in a ventilated and dry environment.

- Strong compatibility:

Suitable for a variety of platemaking equipment such as traditional platemaking machines, UV-CTP and thermal CTP to meet different printing needs.

Technological development and innovation

- Thermal positive plate: A combination of infrared absorbing dyes and acid generators is used. After laser scanning exposure, the acid generator decomposes to change the solubility of the photosensitive layer in the alkaline developer, achieving high sensitivity (650-1300nm wavelength response) and rapid development, while improving chemical corrosion resistance.

- Environmentally friendly formula: Some new plate materials reduce the use of diazo compounds and use photoacid sources (such as hum salts and sulfonyl hydrazones) to replace traditional photosensitizers to reduce the impact on the environment.

- Multi-layer structure optimization: For example, double-coating design, the lower resin layer contains acid generators and infrared absorbers, and the upper thermal layer is responsible for imaging, which can significantly improve the development tolerance and dot sharpness.

Positive plates are widely used in commercial printing (such as books and posters), packaging printing (such as cartons and labels) and special printing (such as metal foils and plastic films). In Southeast Asia, more than 80% of offset printing machines use positive PS plates because of their balanced comprehensive performance and controllable costs. For high-precision printing needs (such as high-end albums), CTCP or thermal positive plates are more advantageous and can achieve a screen count of more than 200 lines/inch.

In short, positive plates for offset printing have become the mainstream choice in the field of offset printing with their precise dot reproduction, reliable printing durability and flexible platemaking adaptability, and the continuous innovation of new materials and processes (such as CTP compatible plates and environmentally friendly formulas) has further consolidated its technical position.

PRODUCTS

ONLINE CONSULTATION

If you have any questions, please contact us and we will contact you as soon as possible.

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.