News

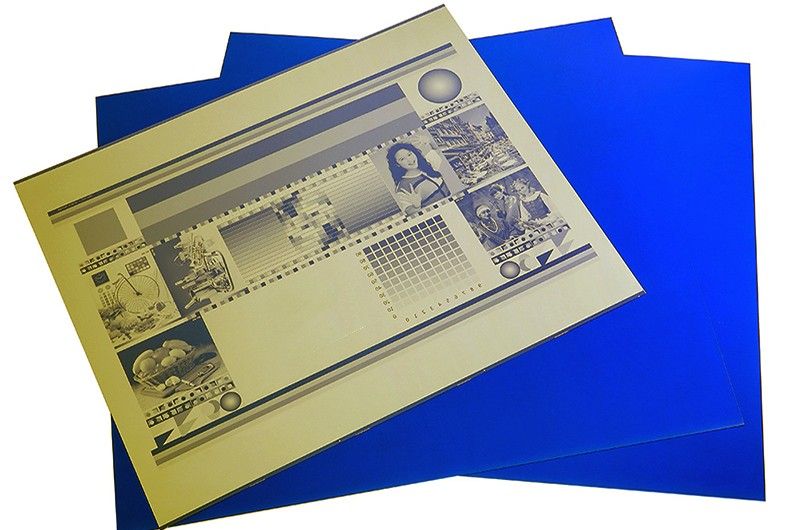

Aluminium lithographic offset printing plates are a widely used type of printing plate in offset lithography. Using an aluminum-based plate as the core, they achieve selective ink adsorption and efficient printing through surface treatment and photosensitive technology.

Structure and materials of lithographic offset printing plates:

The substrate of aluminum offset lithographic printing plates is typically an electrolytic aluminum oxide plate with a thickness of 0.15-0.3 mm. The aluminum plate surface is anodized to form a microporous sand-like structure with a roughness Ra value of 0.5-1.5 μm. This sand-like structure helps retain water and control ink, giving non-image areas hydrophilic and oleophobic properties. A diazo resin or photopolymer photosensitive layer is also coated on the sand-like surface, with a coating amount of approximately 1-3 g/㎡.

Working principle of aluminum lithographic offset printing plates:

Aluminum offset lithographic printing plates belong to the category of offset printing, where the image and non-image areas are almost on the same plane. During printing, the principle of oil-water repulsion is utilized:

Image areas: After surface treatment, they become oleophilic, absorbing ink.

Non-image areas: Through hydrophilic treatment (such as an alumina layer or coating with a hydrophilic colloid), they absorb dampening solution and repel ink.

The ink is indirectly transferred to the substrate (such as paper) via a blanket, achieving high-precision printing.

Core characteristics of lithographic offset printing plates:

1. Material advantages:

Lightweight and durable: Aluminum plates have low density and high mechanical strength, suitable for long-term operation on high-speed printing presses.

Surface stability: After anodizing or electrolytic sandblasting, the aluminum substrate forms a uniform microporous structure (sandblasting), enhancing adsorption capacity and ensuring stable performance of both image and non-image areas.

Corrosion resistance: The aluminum oxide layer (Al₂O₃) has stable chemical properties, reducing erosion from dampening solution or ink components and extending plate life.

2. Printing performance:

High resolution: The sandblasting structure ensures clear image edges, suitable for fine printing (such as color images and text).

High print durability: Aluminum plates exhibit superior abrasion resistance compared to traditional lithography or zinc plates, allowing for single-plate printing yields ranging from tens of thousands to hundreds of thousands of impressions.

High adaptability: Compatible with both sheet-fed and web-based offset printing presses, meeting diverse printing scale requirements.

Plate making process flow of offset lithographic printing plates:

1. Plate pretreatment:

Grinding: Microporous structures are formed on the aluminum plate surface through mechanical grinding, electrolytic sandblasting, or sandblasting, increasing the specific surface area and enhancing adsorption capacity.

Anodizing: An aluminum oxide layer (Al₂O₃) is formed on the aluminum plate surface, improving hardness and hydrophilicity, providing a stable foundation for subsequent photosensitive layer coating.

2. Photosensitive layer coating:

A photosensitive emulsion (such as diazonaphthoquinone sulfonate) is applied to form a uniform photosensitive film for recording image and text information.

3. Exposure and development:

Exposure: The printing plate and film are brought into close contact, and ultraviolet light is used to harden (positive plate) or dissolve (negative plate).

Developing: Unexposed areas are removed using a chemical solution, exposing the hydrophilic aluminum base or image substrate layer.

4. Post-processing:

Coating with a hydrophilic colloid: A substance such as gum arabic is coated onto the blank areas to enhance hydrophilicity and prevent ink adhesion.

Baking: Some printing plates are baked at high temperatures (e.g., 230℃, 5-8 minutes) to improve the hardness and abrasion resistance of the photosensitive layer.

Applications of lithographic offset printing plates:

Commercial printing:

High-volume printing of newspapers, magazines, books, etc., relying on their high durability and low cost.

Packaging printing:

Printing of packaging boxes for food, pharmaceuticals, cosmetics, etc., requiring high resolution and color reproduction.

Advertising printing:

Posters, flyers, etc., utilizing aluminum plates to adapt to different paper types and printing speeds.

Aluminium lithographic offset printing plates have a wide range of applications. Traditional PS plates are relatively inexpensive and suitable for medium to long print runs. With the development of computer-to-plate (CTP) technology, aluminum-based CTP plates have become the mainstream in the market. For example, thermal CTP plates are suitable for long-run printing, while violet laser CTP plates are suitable for commercial quick printing and newspaper printing.

PRODUCTS

ONLINE CONSULTATION

If you have any questions, please contact us and we will contact you as soon as possible.

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.