News

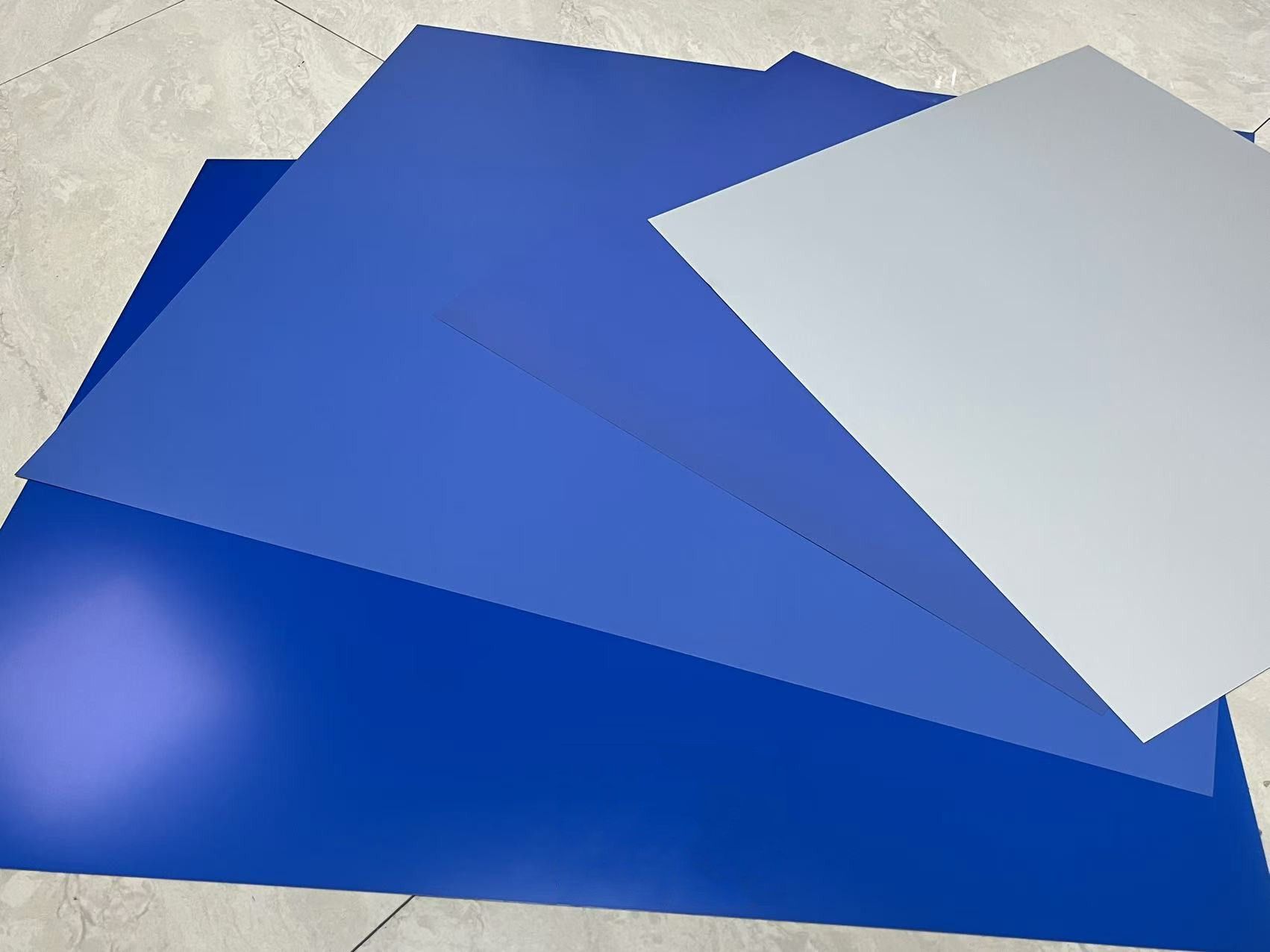

UV CTP printing plates, also known as ultraviolet computer-to-plate (UV CTP) plates, use ultraviolet light (typically with a wavelength of 365-410 nm) as the exposure light source. A computer-controlled laser beam forms an image on the plate surface, eliminating the need for traditional film-based platemaking. They are primarily used in lithographic offset printing and represent a key branch of CTP (computer-to-plate) technology based on UV imaging. Early on, they were widely used by small and medium-sized printing companies due to the low cost of UV light sources.

Components of U VCTP Printing Plates

UV CTP plates are typically multi-layered, consisting of four layers from the substrate to the surface. Each layer has distinct functions and works in tandem to ensure imaging and printing performance:

1. Substrate Layer (Support)

- Aluminum substrate (usually 0.15-0.3mm thick pure aluminum or aluminum alloy plate);

- Provides physical strength and flatness to the plate and supports the upper coating layer;

- Surface graining (electrolytic oxidation or mechanical grinding) increases the specific surface area, improving coating adhesion and ink absorption.

2. Base Coat (Undercoat)

- Polymer resin (such as epoxy resin, polyester resin), coupling agent;

- Improves the bonding between the substrate and the photosensitive layer, preventing the photosensitive layer from peeling;

- Reduces interference from impurities on the aluminum substrate surface with the photosensitive layer, improving imaging uniformity.

3. Photosensitive Layer (Core Functional Layer)

- Photosensitive resin (such as free radical acrylate resin);

- Photoinitiator (UV-sensitive, such as benzophenones and thioxanthones);

- Pigments/dyes (such as carbon black, to adjust the plate color and facilitate post-development inspection);

- Additives (such as stabilizers and plasticizers, to improve storage and printing stability)

- Core Functional Layer: Receives UV light signals and undergoes a photochemical reaction (the photoinitiator decomposes to produce free radicals, which trigger crosslinking and curing of the photosensitive resin);

- Exposed areas cure to form the "printing plate image," while unexposed areas can be dissolved and removed by developer.

4. Protective Layer (Optional)

Polyvinyl alcohol (PVA) or thin polyester film

- Protects the photosensitive layer from dust, scratches and humidity;

- Must be peeled off before exposure (film-like protective layer) or exposed to light (resin-like protective layer, which does not affect UV light penetration).

Working Principle of UV CTP Printing Plates

The imaging and platemaking process for UV CTP plates can be divided into four core steps: exposure → development → baking (optional) → post-processing. Essentially, UV light triggers chemical changes in the photosensitive layer, separating the image and non-image areas:

1. Exposure Phase:

A computer converts the print image data into laser control signals. The UV CTP platesetter's UV laser (such as a semiconductor UV laser) scans the plate's photosensitive layer according to these signals. The photoinitiator in the exposed areas absorbs the UV light energy, decomposing to produce free radicals. These radicals trigger a cross-linking polymerization reaction in the photosensitive resin, forming a cured layer (the "image portion") that is insoluble in developer solution. The photosensitive resin in the unexposed areas remains soluble and unreacted.

2. Development Stage:

The exposed plate enters the developer, where a developer (mostly an alkaline solution) washes over the plate surface. The unexposed, soluble photosensitive resin dissolves and drains with the developer, exposing the aluminum base underneath (forming the "non-image area," or blank area). The cured photosensitive resin remains insoluble in the developer and remains on the aluminum base (forming the "image area," or oleophilic area).

3. Plate Baking Stage (Optional):

To increase the plate's run time (e.g., for high-volume print runs), the developed plate can be heated in a plate baking machine (approximately 200-250°C) for 10-20 minutes. The high temperature further cross-links and cures the photosensitive resin in the image area, enhancing its resistance to abrasion and chemical corrosion. This can increase the run time from 100,000 impressions to over 300,000.

4. Post-Processing Stage:

After baking, the plate undergoes "de-dusting" (removing residual impurities) and "gluing" (applying a protective glue to prevent oxidation and scratching). The resulting UV CTP plate is ready for printing.

Advantages of UV CTP Printing Plates

1. Low Equipment Cost:

The core component of UV CTP platemaking machines—ultraviolet lasers (such as LED UV light sources)—costs significantly less than the infrared lasers (such as YAG lasers) used in thermal CTP plate. Initial equipment investment is only 50%-70% of that of thermal CTP, making it suitable for small and medium-sized printing companies with limited budgets.

2. High Plate Compatibility:

UV CTP plates have low requirements for exposure environments (no strict light protection is required, and short-term operation under normal indoor lighting is not affected). They are also compatible with some traditional PS plate development equipment (requiring only adjustments to the developer parameters). This eliminates the need for a complete production line replacement, reducing upgrade costs.

3. Stable Image Quality:

The UV light wavelength is short (365-410nm), and the laser beam focuses with high precision, achieving a screen resolution of 175-200 lpi, meeting the resolution requirements of mid-to-high-end printing applications such as books, periodicals, and packaging. Furthermore, the photosensitive layer responds evenly to UV light, resulting in sharp edges and reducing issues such as "false edges" and "dot gain."

4. Low Operator Barrier:

The platemaking process does not require complex temperature control (thermal CTP requires strict temperature control to prevent plate oxidation). Development parameters are easily adjustable, allowing operators to become operational after a short training period, reducing labor costs.

UV CTP printing plates, with their core advantages of low cost, ease of use, and strong compatibility, are a cost-effective option for small and medium-sized printing companies upgrading to CTP. Thermal CTP plates, with its high print run, high resolution, and environmental friendliness, is more suitable for companies with high-end printing and high-volume production needs. Both are key components of CTP technology, and the choice should be made based on a company's budget, job type (volume and image quality requirements) and existing equipment.

PRODUCTS

ONLINE CONSULTATION

If you have any questions, please contact us and we will contact you as soon as possible.

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.